Building the Hull

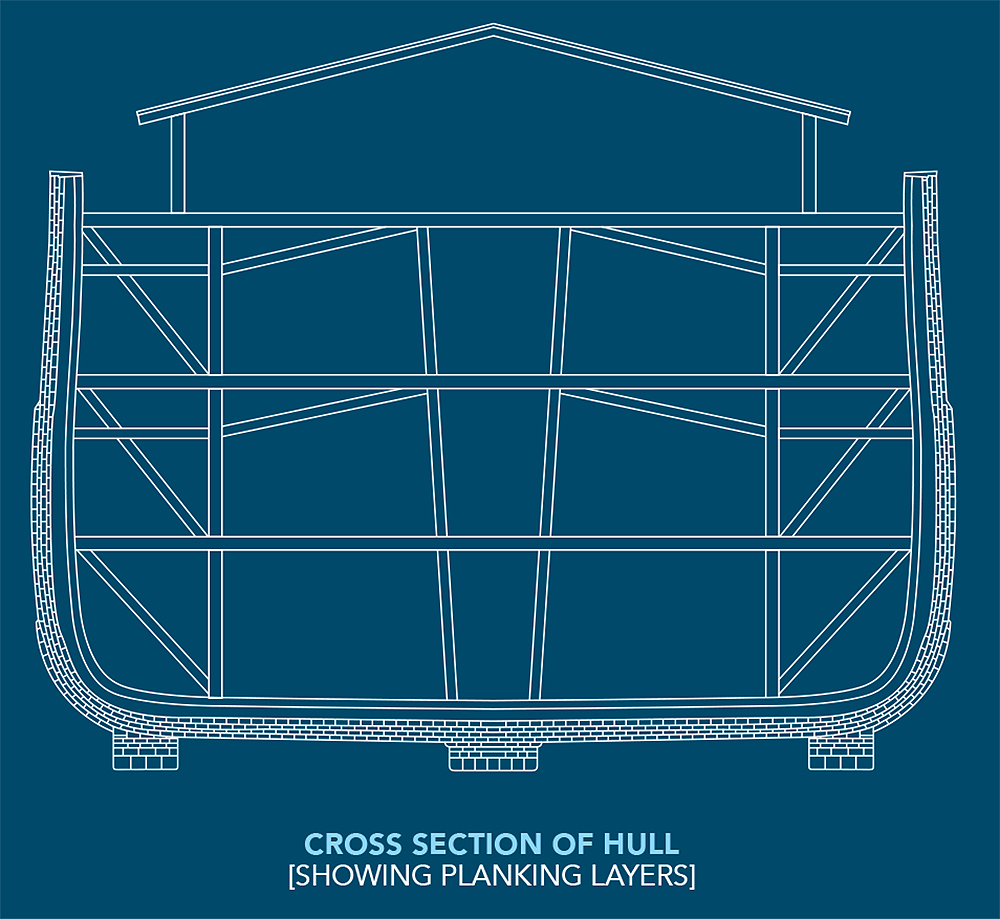

by Ark Encounter on February 22, 2024As you walk into our life-size Noah’s Ark at the Ark Encounter, one of the first things you may notice is the thickness of the hull. So, what was the purpose of each layer?

Waterproofing & Engineering

The problem with long wooden ships is that they tend to flex in the waves, causing the planks to slide against each other and break the waterproofing seal. To solve this problem, the hull must be constructed in a way that prevents the planks from sliding.

Multiple Layers

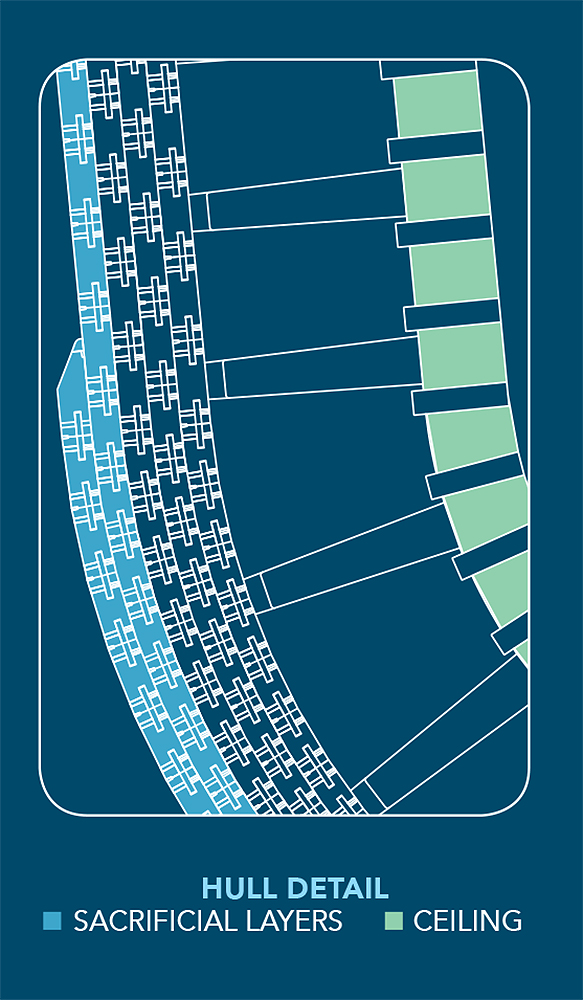

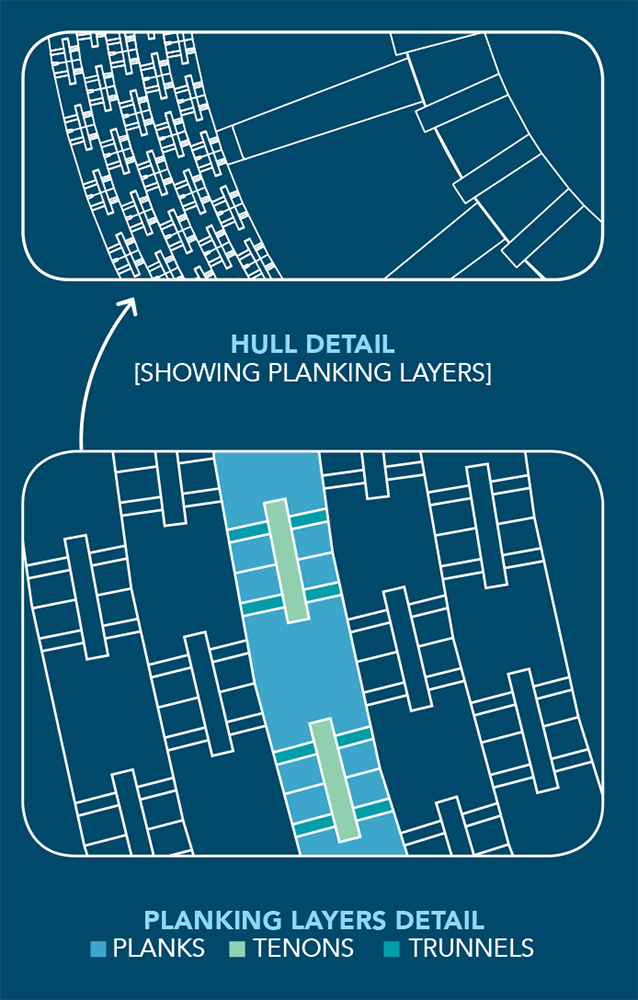

The Ark Encounter design features three layers of structural planking to improve shear resistance in the hull. It also includes two outer sacrificial layers below the waterline to protect against damage from scraping and collision.

Edge-Jointed Planking

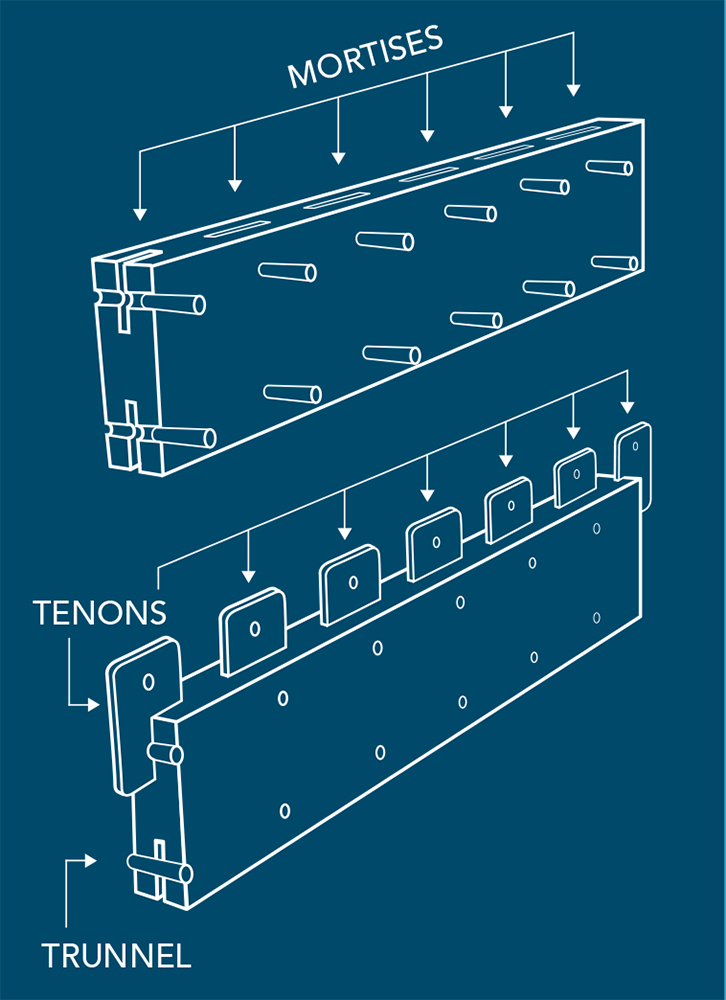

Ancient Greek ships featured planking with mortise and tenon joints. These interlocking pieces would prevent the planks from sliding and loosening up.

Trunnels

Large wooden dowels driven through pre-drilled holes would further protect against sliding planks. Also, the wooden trunnels would expand in water, making a watertight and permanent connection.

Pitch

God told Noah to coat the ark inside and out with pitch. Since petroleum-based pitch formed as a result of the flood, the pitch Noah used was likely made from tree resin, providing further waterproofing for the ark.

Start planning your trip to the Ark Encounter today, and take a close look at the hull as you enter the life-size Noah’s Ark.